Foam is a remarkably versatile material, essential across numerous industries for its unique properties. Its structure—a matrix of trapped gas bubbles—allows it to be customized for a vast array of applications, offering benefits from cushioning and insulation to structural support. This guide provides a professional overview of the primary types of foam and their key uses.

Core Classifications: Open-Cell vs. Closed-Cell

The fundamental distinction in foam products lies in their cellular structure.

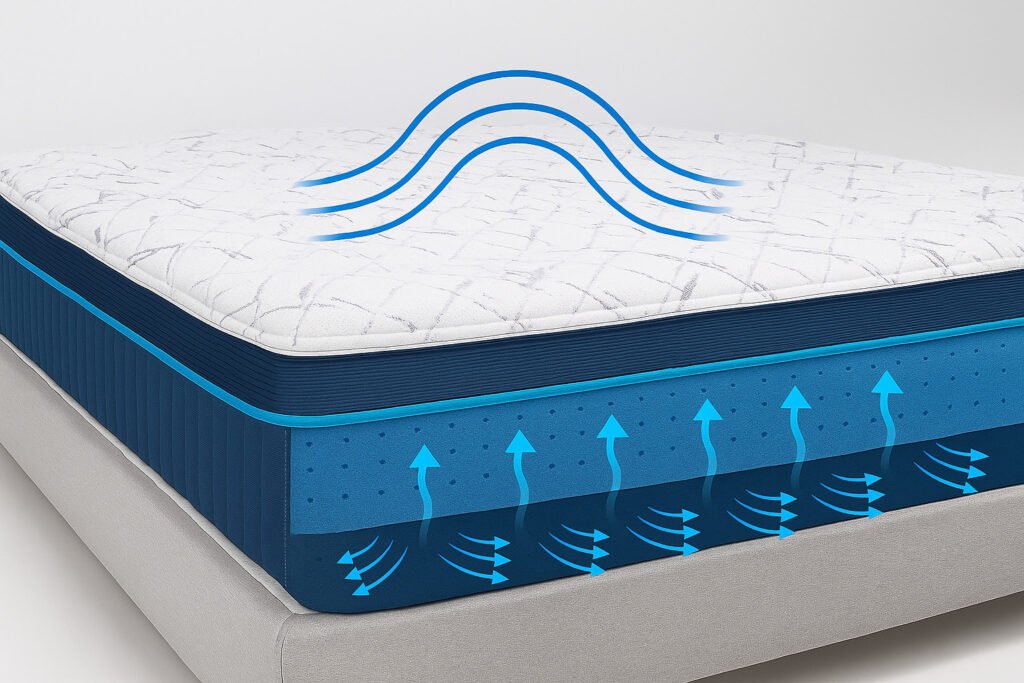

- Open-Cell Foam: This type features interconnected air pockets, allowing air and liquids to pass through. It is characterized by its softness, low density, and high compressibility. Common applications include mattresses, upholstered furniture, and soundproofing materials, where breathability and flexibility are paramount.

- Closed-Cell Foam: In this structure, air pockets are sealed and isolated. This makes the foam more rigid, water-resistant, and an excellent insulator. It is used in products requiring thermal insulation, buoyancy, and durability, such as athletic equipment, packaging, and building insulation.

Key Foam Types and Their Industrial Applications

The polymer used determines a foam’s specific properties and suitability for a particular application.

- Polyurethane (PU) Foam: This is the most widely used and adaptable foam.

- Flexible PU Foam (Open-Cell): Utilized for its comfort and support in products like mattresses, pillows, and car seats.

- Rigid PU Foam (Closed-Cell): Valued for its high thermal resistance, it serves as a primary material for insulation panels and refrigerated transport.

- Memory Foam: A specialized, viscoelastic polyurethane foam that contours to pressure and heat. It is a premium choice for orthopedic support in mattresses and medical cushions due to its superior pressure-relieving capabilities.

- Polyethylene (PE) Foam: A durable, lightweight, and closed-cell foam known for exceptional shock absorption. Its applications include protective packaging, joint expansion fillers, and buoyant materials.

- Expanded Polystyrene (EPS) Foam: Commonly known as Styrofoam, this rigid, closed-cell foam is celebrated for its low cost and high thermal efficiency. It is the industry standard for disposable food containers, protective packaging, and architectural insulation boards.

- Ethylene Vinyl Acetate (EVA) Foam: A flexible, closed-cell foam that provides excellent shock absorption and water resistance. It is extensively used in footwear, sports equipment (e.g., yoga mats), and protective padding.

Conclusion

Foam products are far more than simple filler materials; they are engineered solutions that provide critical functionality across diverse sectors. From enhancing comfort and safety to improving energy efficiency and product longevity, the strategic use of the right foam type is essential for modern product design and construction. Understanding these material properties is key to making informed decisions that deliver superior performance and value.